alumina ceramic что это

Глиноземистая керамика поликристаллический материал

Благодаря своей доступности и свойствам, Al2O3 очень часто используется для производства керамических компонентов. Глинозем используется в различных модификациях. Наиболее часто для технической керамики используется треугольный α-Al2O3 (корунд). Для получения оксида алюминия бокситы из натурального сырья перевариваются в каустическую соду по технологии Bayer для получения гидроксида алюминия. При спекании или кальцинировании во вращающихся печах она лишается воды и образуется оксид алюминия.

Благодаря своей твердости и высокой износостойкости, глинозем часто используется в качестве шлифовального или полировального средства. Поскольку температура плавления выше 2000 ° C, материал идеально подходит для использования в качестве огнеупорного материала. Al2O3 используется в электротехнике благодаря низкому коэффициенту диэлектрических потерь и высокой электрической изоляции и прочности диэлектрика. Области применения варьируются от уплотнительных дисков в метчиках до имплантатов и баллистической защиты из оксида алюминия.

Свойства материала окись алюминия в значительной степени зависят от чистоты и производственного процесса. С увеличением доли глинозема повышается твердость, коррозионная стойкость, диэлектрическая прочность и теплопроводность материала. Однако сопротивление термическому удару снижается.

Alumina Systems GmbH использует два керамических материала в соответствии с DIN EN 60672 благодаря своим превосходным электрическим свойствам и хорошей металлизации: C795 с 96% Al2O3 и C799 с 99,7% Al2O3.

Ceramic Tube / Ceramic Rod / Ceramic Plate / Ceramic Valve / Ceramic Plunger / Ceramic Pump Manufacturer

Focus on Alumina / Zirconia ceramic parts R&D and production

Zirconia Ceramic Parameters

Alumina Ceramic Parameters

Silicon Nitride Ceramic

ZTA Toughened Ceramic

Aluminum oxide ceramics is very hard and resistant to wear, providing high compressive strength even in extreme temperatures and corrosive environments.Alumina is also an excellent electrical insulator and gas tight.

Typical Alumina property include:

Good strength and stiffness

Good hardness and wear resistance

Good corrosion resistance

Good thermal stability

Excellent dielectric properties (from DC to GHz frequencies)

Low dielectric constant

Low loss tangent

Others

Alumina ceramic composition(Al2O3 purity 95% to 99.99%):

High purity alumina ceramics

99.99% Alumina ceramic; 99.9% Alumina ceramic,

Ordinary alumina ceramics

99.7% Alumina ceramic,99.5% Alumina ceramic,99% Alumina ceramic,97% Alumina ceramic,96% Alumina ceramic,95% Alumina ceramic

Note: different industries, different environments, different equipment, different products have different requirements on the composition of alumina, different alumina ceramic components have different performance and service life.

Alumina ceramics are currently classified into high-purity and ordinary types. High-purity alumina ceramics are ceramic materials with Al2O3 content above 99.9%; due to their sintering temperature as high as 1650-1990 ° C, the transmission wavelength is 1

6 & mu; m, generally made of molten glass to replace platinum crucible; Translucent and alkali-resistant metal corrosion are used as sodium lamps;

Alumina Ceramic Parameters

| Properties | Unit | Alumina (AL2O3) | |||

| AL2O3≥95 | AL2O3≥99 | AL2O3≥99.5 | AL2O3≥99.8 | ||

| Volumetric density | g/cm3 | 3.7 | 3.80-3.85 | 3.85 | 3.9 |

| Hardness | HRA≥ | 86 | 88 | 88 | 88 |

| Flexural Strength | Mpa≥ | 300 | 350 | 400 | 400 |

| Maximum temperature | в„ѓ | 1500 | 1500 | 1500 | 1500 |

| Line expansion coefficient | ×10-6/в„ѓ | 7.5 | 8.2 | 8.2 | 8.2 |

| Dielectric constant | εr(20в„ѓ,1MHz) | 9 | 9.2 | 9.2 | 9.2 |

| Media loss | tanδ×10-4,1MHz | 3 | 2 | 2 | 2 |

| Volumetric resistivity | Ω·cm(20в„ѓ) | 1013 | 1014 | 1014 | 1014 |

| Breakdown strength | KV/mm,DC≥ | 20 | 20 | 20 | 20 |

| Acidic resistance | mg/cm2≤ | 0.7 | 0.7 | 0.7 | 0.7 |

| Alkaline resistance | mg/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Abrasion resistance | g/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Compressive strength | Mpa≥ | 2500 | 2500 | 2500 | 2800 |

| Flexural Strength | Mpa≥ | 200 | 350 | 350 | 350 |

| Thermalcoefficient | W/m·K(20в„ѓ) | 20 | 25 | 25 | 25 |

Note: The above table is made by Mingrui ceramic manufacturer, the table is part of the parameters of alumina ceramics, All specific alumina ceramic parameters, please contact us.our officials E-mail: admin@cerampart.com

| Properties of Alumina/Aluminum Oxide (Al2O3) 1.Very good electrical insulation (1×10^ 14 to 1×10^ 15 Ωcm) 2.Moderate to extremely high mechanical strength (300 to 630 MPa) 3.Very high compressive strength (2,000 to 4,000 MPa) 4.High hardness (15 to 19 GPa) 5.Moderate thermal conductivity (20 to 30 W/mK) 6.High corrosion and wear resistance 7.Good gliding properties 8.Low density (3.75 to 3.9 g/cm3) 9.Operating temperature without mechanical load 1,000 to 1,500°C. 10.Bioinert and food compatible | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

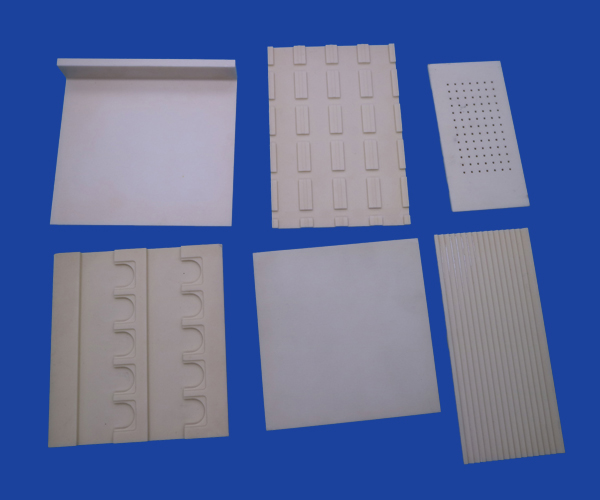

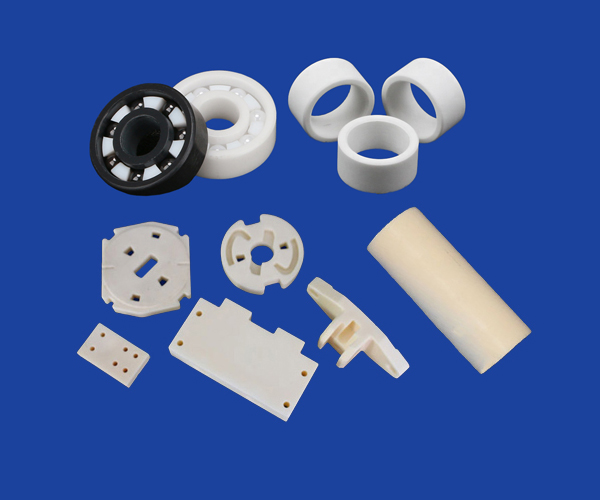

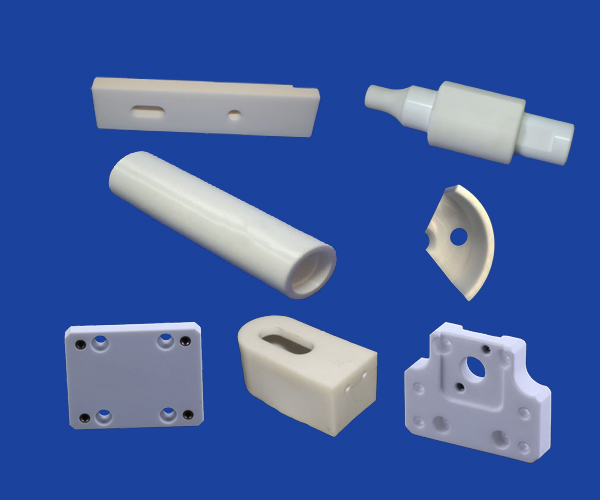

| Products and Aplications – Pieces, Plates, Boards, Trays, etc. in Alumina-Ceramic / Cordierite-Mullite 90-98% Alumina Ceramic (Al₂O₃)Our portfolio of 90-98% alumina materials are suitable for a variety of our ceramic products used in a range of applications. These materials include but are not limited to: 92% Alumina This material is a highly versatile alumina ceramic with great mechanical, electrical, thermal, and chemical properties, featuring: The above features of this material, make this the right choice for applications such as electrical packages, bushings, grinding media, wear resistant components and other general industrial applications that would benefit from the unique properties of this material. AL-500 ® (94% Alumina) This 94% AL203 material has an excellent combination of mechanical, thermal, electrical and chemical properties which are well suited to applications within many industries. This material benefits from the following features: The above features along with the exceptional properties of this material make this suited to a variety of applications including pressure sensors for fluid flow measurement, wear and barrier coatings for sputtering targets, electron tube and laser components, etc. A950 (95% Alumina) Our A950 Alumina ceramic offers significant advantages over other materials such as glass. It has a minimum Al2O3 content of 95%, making it a stable and reliable material that delivers benefits in a variety of settings. This material benefits for a number of features including: Stronger and more robust than glass A950 Alumina ceramic is good for making ceramic-to-metal feedthroughs, X-ray component feedthroughs, high voltage bushings and products for implantable medical device applications. Sintox FA Ballistic (95% Alumina) This is a lightweight hard-faced 95% (typically 96%) alumina material especially formulated for ballistic applications. This material features: This material, along with our Sintox CL (98.6%) alumina, is the best choice for military applications including ergonomic body armour for defence and security services and armour tiles for battlefield vehicles. Sintox FA Metallising (95% Alumina)This 95.0% alumina has been specially formulated for accurate grain size which is particularly valuable when a ceramic microstructure is needed to provide a good keying surface for high integrity molybdenum metallising. This material features: These features mean this material is an excellent choice for metallised products in applications such as high vacuum equipment and scientific instruments where ceramic components need to be brazed to form high strength connections and complex assemblies, insulators for probes and sensors, transducer components, insulators for vacuum pumps, gun assemblies and connectors for X-ray tubes and electron microscopes. Sintox FA (95% Alumina) This refractory-quality 95% alumina material is extensively used for high temperature applications in welding, heat treatment, and metallurgical and chemical processing. This material features: The above features make this material the right choice for applications such as welding nozzles, stress relieving beads, thermal insulators to protect work pieces during welding and heat treatment and special crucibles for metallurgical and chemical processes. Sintox FF (95% Alumina) This material is a high quality electrical insulator, with good mechanical properties, that is widely used for components in consumer products as well as for high integrity applications. Featuring: This material is versatile enough to be used for products in a variety of applications such as laser power tubes, telecommunications components, aerospace components, automobile components, domestic product components, process equipment components. 96% Alumina This also is a high purity alumina ceramic with excellent mechanical, electrical, thermal, and chemical properties, benefiting from the following features: The features of this material make this the right choice for applications such as electrical inductors, switches, bushings, seal rings, pump seals, electronic packages, bearings and wear resistant components as well as a wide range of industrial applications that would benefit from the properties of this material. AL-600 ® (96% Alumina) We also offer another version of our 96% alumina which is great for medical applications. This material has an excellent combination of mechanical, electrical, thermal and chemical properties and benefits from the following features: The combination of these properties and features makes this material the best choice for applications such as wear nozzles, wear guides, blood valves, electrical connector housings and general industrial applications where its range of excellent mechanical, electrical and chemical properties prove advantageous. Hilox™ 961 (96% Alumina) This material is a high quality alumina ceramic of 96% AL2O3 content. Excellent mechanical characteristics make this an ideal material for components where resistance to dynamic wear and abrasive action are prime factors. This material benefits from the following features: The excellent properties and features of this material make this suited to applications such as valve plates for liquid and gas control systems: industrial and domestic applications. Deranox 970 (97% Alumina) This material 97% alumina material is an excellent electrical insulator that can be metallised to facilitate high-temperature brazing of assemblies. This material features: The fact that this material can be metallised makes this a good choice for many ceramic to metal or brazed assemblies such as high-vacuum systems, laser equipment (gas, solid-state and waveguide), X-ray tubes and electron microscopes, microwave windows and insulators in medical and scientific equipment. Deranox 975 (97.5% Alumina) This is a high quality, fine grain material widely used for electrical and mechanical components that require thick film metallising, as well as for dynamic applications where resistance to abrasion and chemical attack are essential. The main features of this material are: These features make this material an excellent choice for products in a variety of applications such as thick film metallied components, such as those with conductor and/or resistor networks, dielectric layers, solderable interfaces, etc, high-integrity devices for duties in the defence, aerospace, medical, laser and scientific instrument fields, dynamic and static components in pumps and valves that handle corrosive or abrasive media. AL-300 ® (97.6% Alumina) This is a top quality alumina ceramic of 97.6% Al2O3 content, widely used for high integrity components where its exceptional electrical and thermal properties are essential to operational stability and reliability. Features of this material include: The properties and features exhibited in this material ensure AL-300 ® is an excellent material for manufacturing products such as laser components, electro-optical equipment, flow measurement devices, pressure sensors, klystron power tubes and X-ray equipment used in defence, medical and communications markets. We have the ability to offer tailored formulations to suit a particular requirement, so contact us today to see how we can work with you to ensure you have the right material that provides full optimisation for your product. Подложка Alumina ceramic (TO-220)Для доставки в город [name_city] мы пользуемся услугами Почты России. Процесс оформления заказа на сайте: Выбираете необходимый товар и кладете его в корзину Выбираете транспортную компанию и пункт выдачи Оплачиваете заказ онлайн В течении нескольких часов мы свяжемся с Вами на электронной почте и вышлем номер отслеживания посылки Доставка заказов от 1000 руб. – бесплатно. Заказы менее 1000 руб. оплачивается товар и стоимость доставки Стоимость доставки указывается при выборе нужного пункта выдачи. Доставка курьером оплачивается отдельно в независимости от суммы заказа. По вопросам доставки другими транспортными компаниями звоните по телефону Оплата заказов производится во время оформления заказа. Работаем по предоплате. Для оплаты заказа онлайн предлагаем использовать банковские карты, как самый безопасный способ оплаты. Обратите внимание! На сайте «Проконтакт. Всё для радиотехника» установлено безопасное подключение. Никто, кроме Вас не имеет доступ к данным банковских карт! Принимаем безналичную оплату с НДС. Наша компания выставляет счет организациям на сумму заказа от 349 руб., условия доставки обсуждаются персонально. Делайте заказ на сайте со способом оплаты Банковский перевод (для юридических лиц), либо присылайте необходимые позиции и реквизиты вашего банка на нашу электронную почту info@procontact74.ru Описание процесса передачи данных при оплате онлайн Оплата с использованием дебетовых и кредитных карт следующих платежных систем: Visa, MasterCard, Maestro, МИР. При оплате с помощью банковской карты Вам необходимо предоставить следующие данные: Возврат товара в течении 45 дней!После покупки у Вас есть 45 дней, чтобы вернуть товар, который не подошел, не понравился, не пригодился, и даже если он не подходит к дизайну вашего рабочего места! Товар должен иметь товарный вид, заводскую упаковку, то состояние, в котором Вы его получили Inert Alumina Ceramic BallsInert ceramic (porcelain) balls are used to fill and support the catalyst layer in catalytic columns and reactors, and as grinding bodies in ball mills. The balls are made of high quality solid pressed silicate porcelain with an aluminum oxide content of Al2O3 – 23% (in the range of 23-26%). They have high mechanical strength, resistance to acid, alkali, and some organic solvent, and resistance to thermal shock, which makes them all ideal choice for support of all types of catalysts. Inert Ceramic Balls for Catalyst Bed Support Media are available to the order of sizes from 3 mm to 50 mm in diameter (1/8 – 2 inch). Ball Colour: white or light grey. Shape: Sphere (Solid). Other types of ceramic products can be made upon your request indicating the necessary technical data. Our company is engaged in the production and sale of ceramic packing, including Inert Alumina Ceramic Balls. All our products pass strict quality control and comply the necessary standards. Since we are a manufacturer and dealership margins are not included in the price of the final product, we have a low price for Ceramic Balls. Corresponding quality documents are provided. Detailed technical specifications and dimensions Ceramic Balls are shown below. The final price for Inert Ceramic Balls depends on the quantity, delivery terms and form of payment. For questions regarding the acquisition of Ceramic Balls, send an email request to: And we will provide you a commercial offer for delivery. We are open to manufacture products at our production facilities Common Specifications of Inert Alumina Ceramic Balls:

Packing and mechanical properties of Inert Ceramic Balls:

Chemical composition for 23% Inert Alumina Ceramic Ball:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||